Current social and ecological challenges demand innovative solutions for the efficient use of resources associated with an increased use of renewable raw materials. In the field of lightweight construction, natural fiber-reinforced biopolymers are a promising candidate for fulfilling the requirements for ecological compatibility while providing advanced material performance.

Natural fibers, such as flax, hemp or cotton, have been extensively studied throughout the recent years to evaluate their qualifications for mechanical reinforcement of lightweight parts. To further improve the performance and reliability of the respective composites, structural health monitoring in the fields can be a powerful tool for future material development.

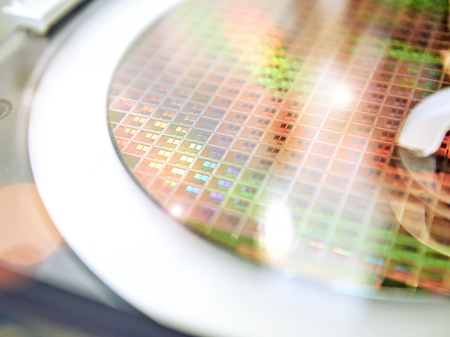

Printed sensors on biocompatible substrates, such as paper, are well-suited for the integration into the respective lightweight parts during manufacturing, as the flexible 2.5D-structure does not inherently affect the material properties as bulky and rigid 3D-silicon based sensors would. In addition, paper is a low-cost, easily available, sustainable and biologically degradable material and its application for printed electronics has lately been of great scientific interest.

Speaking of sustainability, digital additive electronics manufacturing technologies, such as inkjet printing, are considered to have a low environmental impact provided that also eco-friendly materials are used. Consequently, the aim of the project “Smart Lightweight 4.0” was the development of fully additively manufactured paper-based sensors for the integration into lightweight components, such as rotor blades for small wind turbines, car body parts and medical protheses. The project was initiated and conducted by three research institutions of the province of Carinthia: Kompetenzzentrum Holz GmbH, Silicon Austria Labs GmbH and University of Applied Sciences Carinthia.

This uses the expertise of these research institutions synergistically and generates benefits on several levels. A critical mass that goes beyond the sum of the individual activities was created, conducting research on strategically relevant as well as sustainable topics and, in the course of the business development and funding process, forming a fundamental basis for new spin-offs.

Sensor development and integration

A stable inkjet-printing process on uncoated paper substrate was established considering ink wetting, resolution and other printing parameters. As paper is a low-cost, easily available, sustainable and biodegradable material, the fabrication of paper-based electronics can be considered as active contribution addressing ecological challenges of our time.

Based on that, three different types of sensors were developed for measuring temperature, humidity and strain inside of the lightweight material. All sensors were thoroughly characterized using the sophisticated SAL infrastructure and their performance was evaluated for the given use case of structural health monitoring of natural fiber reinforced lightweight parts. The mechanical integrity of the lightweight part was not reduced by the integrated sensor, instead its strength even improved. All sensors under test remained functional after the vacuum infusion process and continued to provide measurement data. In addition, the possibilities of wireless sensor read-out were explored.

The sensors developed as part of the project “Smart Lightweight 4.0” can be considered as game changing in the fields of additive, low-cost and environmentally compatible ubiquitous sensing, which paves the way toward sustainable and “green” electronics for the future.

This project is co-financed by the European Regional Development Fund (EFRE). http://www.efre.gv.at/

![[Translate to English (US):] A close up of a printed sensor](/fileadmin/_processed_/d/b/csm_SAL_Villach_2021_Helge_Bauer__137__3305b0f6fd.jpg)

![[Translate to English (US):] [Translate to English (US):]](/fileadmin/_processed_/8/7/csm_AdobeStock_269568606_58f63f40ca.jpeg)