- Title: BCI modeling and test

- Cooperative research project

- Project Duration: 10.1.2019 - 31. 10. 2019

BCI Modeling and Test

Project Objectives

Electronic system and sub-components need to withstand a measure of electromagnetic interference during their daily operation. To ensure proper functionality and safety, electronic products are tested on electromagnetic compatibility before being released on the market. Amongst others, the bulk current injection (BCI) test is a component test on electromagnetic immunity standardized by ISO 11452-4. It is a mandatory test for automotive applications.

Evaluating electromagnetic susceptibility of a new design by use of fabricated prototypes is costly and time consuming, as it might require many re-design cycles until the product complies with all regulations. Consequently, much effort is made worldwide to enable verification of electronic device´s electromagnetic performance by simulation.

In this project a simulation model of the entire BCI test setup was developed, which allows to properly estimate the immunity behavior of a device under test by simulation, without existing physical prototypes or actual measurement setups. By application of such simulation environment a device under development can be tested in the virtual domain, which saves time and money by preventing the necessity for re-designs due to compliance failure of the fabricated prototype.

In more detail, scope of the project was the

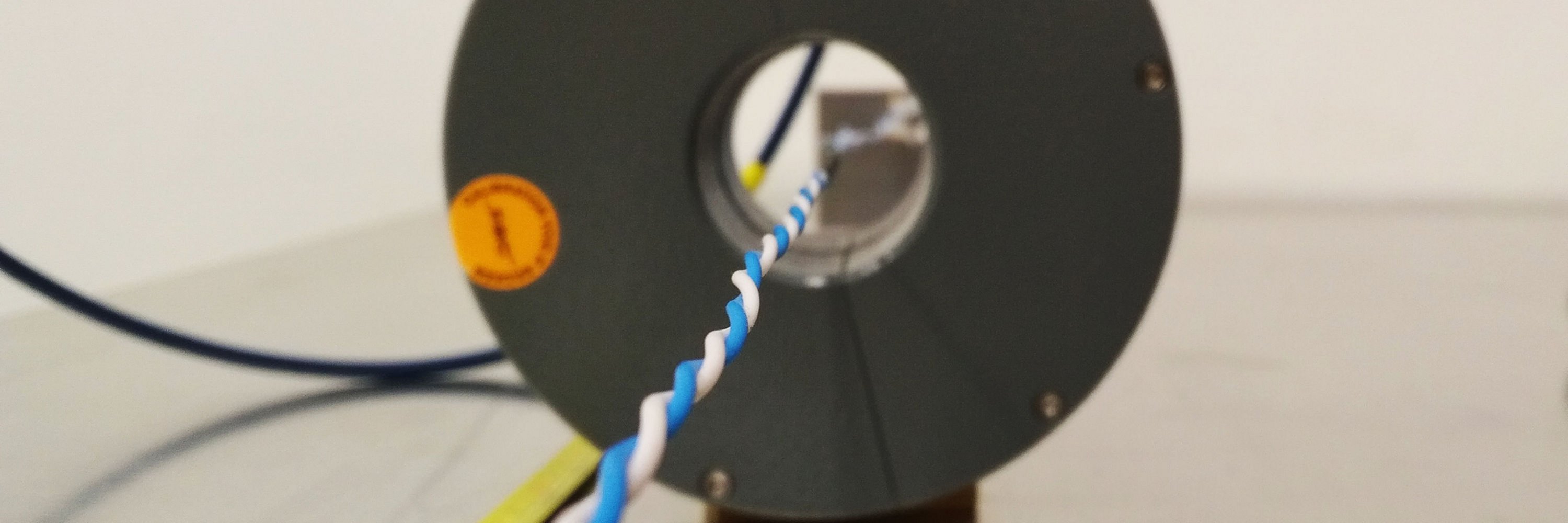

- execution of immunity measurements following the BCI method of a device under test (positioning device) connected to an Electronic Control Unit (ECU) by an automotive-type cable harness.

- development of an equivalent lumped circuit model (composed of R-L-C elements) of the BCI setup for the use in transient circuit simulations. For high versatility with respect to different types of cable harnesses, lumped circuit transmission line (LCTL) technique was applied to enable fast generation of cable models.

- creation of a 3D model of the complete BCI setup to enable the investigation of impact factors on the test results using the virtual testbench. The 3D model was set up in a generic fashion to effortlessly allow modifications in the test setup.

- establishment of procedures to transfer parameters from the generic 3D model to the equivalent circuit model, enabling fast evaluation of the impact of setup changes in the circuit domain.

Project facts

Your contact person

DI Dr. Bernhard Auinger

Head of Research Unit | Coexistence & Electromagnetic Compatibility (CEMC)

e-mail: contact@silicon-austria.com

Research program

Cooperative research project, which belongs to SAL research program 1 “Virtual Prototyping and Model based Design with Hardware-in-the-Loop (HIL)”.