The electrification of the vehicle powertrain has ushered in a new era for power electronic systems. Besides maximum efficiency and reliability, as is the case with power electronic components used in power plants for energy conversion, electromobility places further demands on such components. Minimum installation space, operation under extreme environmental conditions and, at the same time, high efficiency are required of power electronic systems. In the "Tiny Power Box" project, the focus is on optimizing the power density and efficiency for a charger integrated in the electric car, a so-called onboard charger. The aim of the project is to reduce weight, use fewer components and less space, as well as to avoid losses during charging of the vehicle battery.

In addition, the onboard charger has been designed with selected components to enable bi-directional energy transfer. The electricity that has been stored in the vehicle battery via the charging port, can thus also be reused in the opposite direction. In this so-called “vehicle-to-home” concept, the vehicle's battery serves as an energy source or intermediate storage for other applications. In combination with photovoltaic systems, vehicle-to-home can therefore represent an interesting usage scenario, as the energy required in the private household in the evening can simply be provided by the electric car, which is charged with solar energy during the daytime. The incentive for private users is particularly great, as this method maximizes the degree of self‑sufficiency and the self-produced surplus energy of the solar cells can be used cost-efficiently without having to make up the difference between the feed-in tariff and the electricity tariff for electricity purchases during times without PV production on the electricity bill. It is obvious that every single percent in efficiency, which is converted into losses in the power electronic system, is undesirable. Current onboard chargers have charging efficiencies of around 95 %. In the Tiny Power Box project, the target was defined by more than 98 % for charging and discharging the battery. The foundation for vehicle-to-home and other future scenarios such as the implementation of grid-serving services is laid with the high efficiency of the on-board charger in the Tiny Power Box project.

Lighthouse example of cooperating along the value chain

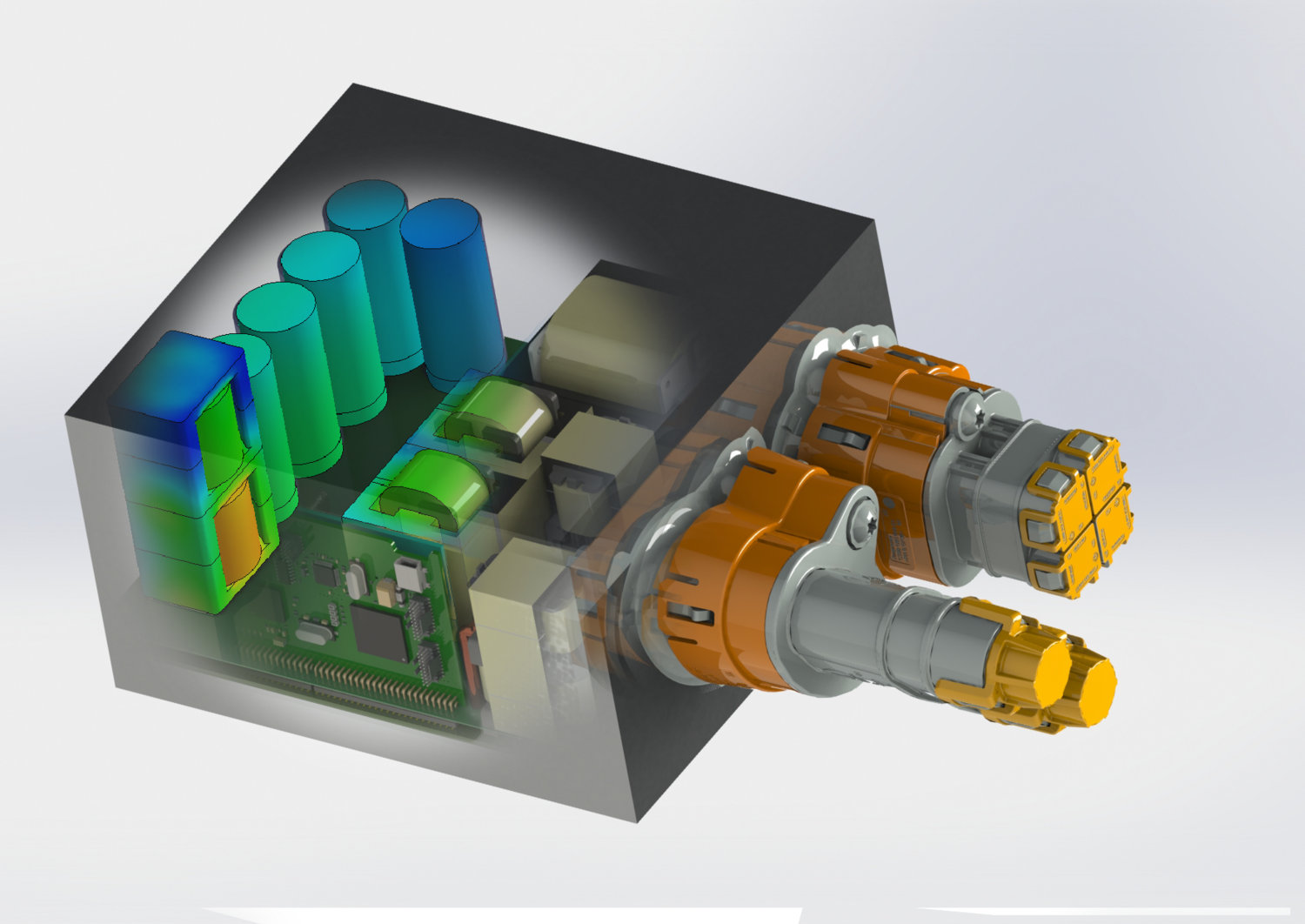

The use of the latest semiconductor technologies and components, some of which are still at the trial stage, will enable the team to achieve these very ambitious project goals. The project partners involved are located along the entire value chain, from component manufacturers to system providers, and are conducting research together with Silicon Austria Labs on the best possible integration of the components and optimization of the on-board charger presented. A key factor here is system modeling and simulation even before the actual realization of the system. This means, for example, that thermal problems caused by the high power density and the compact placement of components can be identified at an early stage without having to build a prototype in the laboratory. A so-called design-by-simulation workflow reduces the number of re-design phases and enables a faster realization of an application-oriented prototype. As one of the core competencies of the SAL research team, this workflow is therefore used to optimize the on-board charger in terms of size, efficiency and thermal performance. "After completion of the simulations, the first components of the prototypes are currently in the manufacturing process, which will be evaluated in the laboratory over the next few months," says Christian Mentin, Project Manager and Scientist in the Power Electronics division at SAL, about the current status of the project.

This project is a showcase example in the field of power electronics for the cooperation between the research center SAL and the five participating lead companies Fronius International GmbH, Infineon Technologies Austria AG, AT & S Austria Technologie & Systemtechnik AG, TDK Electronics GmbH & Co OG and AVL List GmbH. At the same time, the broad industry participation shows that jointly achieved research results can be made usable for different applications and along the entire value chain, thus sustainably strengthening Austria's innovative power.