Intelligent and wireless condition monitoring

Food packaging made from sustainable raw materials such as paper is already a promising alternative to conventional plastic or aluminium packaging. However, the specific requirements for food packaging continue to pose challenges. One important aspect to consider is the control and monitoring of the moisture content within the protective atmosphere. Deviations from this can encourage the growth of bacteria, yeasts and moulds. By monitoring and controlling the moisture content in food packaging, the risk of microbial growth can be significantly reduced and the correct consistency of the product can be maintained.

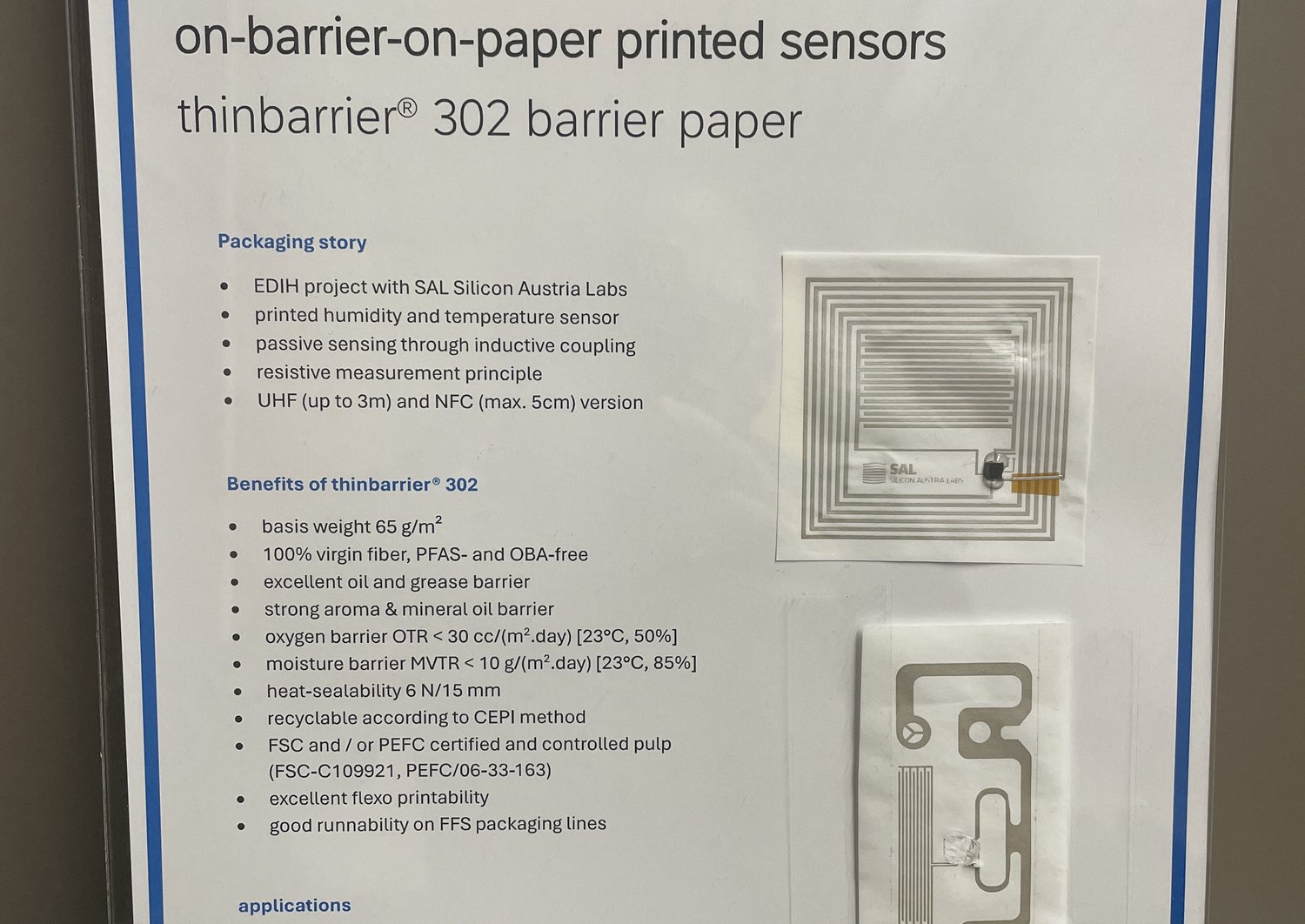

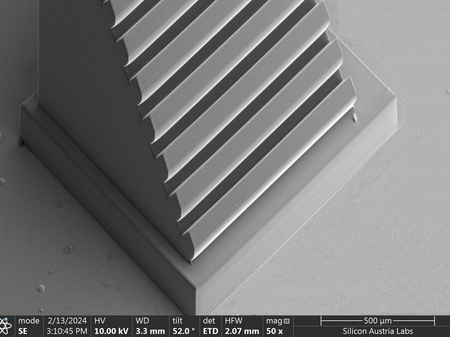

The R&D company DELSCI GmbH is working on environmentally friendly packaging solutions, mainly made of paper. Together with SAL, they have now developed a demonstrator for intelligent condition monitoring of food products. The aim was to design a sensor sheet equipped with a humidity sensor and an RFID tag. The special feature is that the sensor is based on food-safe material and is integrated into the packaging using special printing techniques. The RFID tag is used to wirelessly record the information required for inspection. Specifically, three printed UHF tag demonstrators and 10 NFC sensor tags have been developed by SAL as part of the project.

"These demonstrators developed together with SAL represent a first successful initiative towards a sustainable and intelligent packaging solution for in-situ condition monitoring of sensitive products. It is a great example of the enormous potential that lies in cross-industry innovation activities," says Herwig Kirchberger, Managing Director DELSCI.

Combined knowledge

RFID (Radio Frequency Identification) is used to identify and track objects. The technology is based on radio waves and enables the recording, exchange and use of data between a reader or writer and a chip. Depending on the application, different RFID frequencies are used, including low frequency (LF), high frequency (HF) and ultra high frequency (UHF). Near Field Communication (NFC) technology is a subset of HF RFID.

In addition to the paper samples provided by DELSCI, PET and PI polymer films were used as substrates for printing the sensors. An impinj reader and a Kathrein mid-range antenna were provided to complete the UHF setup. Software was also configured to track humidity and temperature changes in real time.

The project promotes digitization through the combined use of additive manufacturing, system integration and printed electronics, providing a smart solution for packaged food. The developed demonstrator was already presented at this year's FACHPACK in Nuremberg from September 24th to 26th.

"We have developed a solution that not only supports environmental goals, but also enhances food safety through real-time monitoring of critical parameters such as moisture. This project demonstrates how collaborative efforts in additive manufacturing and digital technologies can lead to highly innovative and environmentally friendly packaging solutions. Together with our partners, we're pushing the boundaries of what's possible in smart packaging and paving the way for a more sustainable future for the packaging industry”, states Tutku Bedük, respective project leader at SAL.

The project is part of the funding program European Digital Innovation Hub (EDIH) - Applied CPS. Read the success story of this project here:

Success Story EDIH Applied CPS

DELSCI works closely with delfort, a leading company for functional paper packaging solutions.