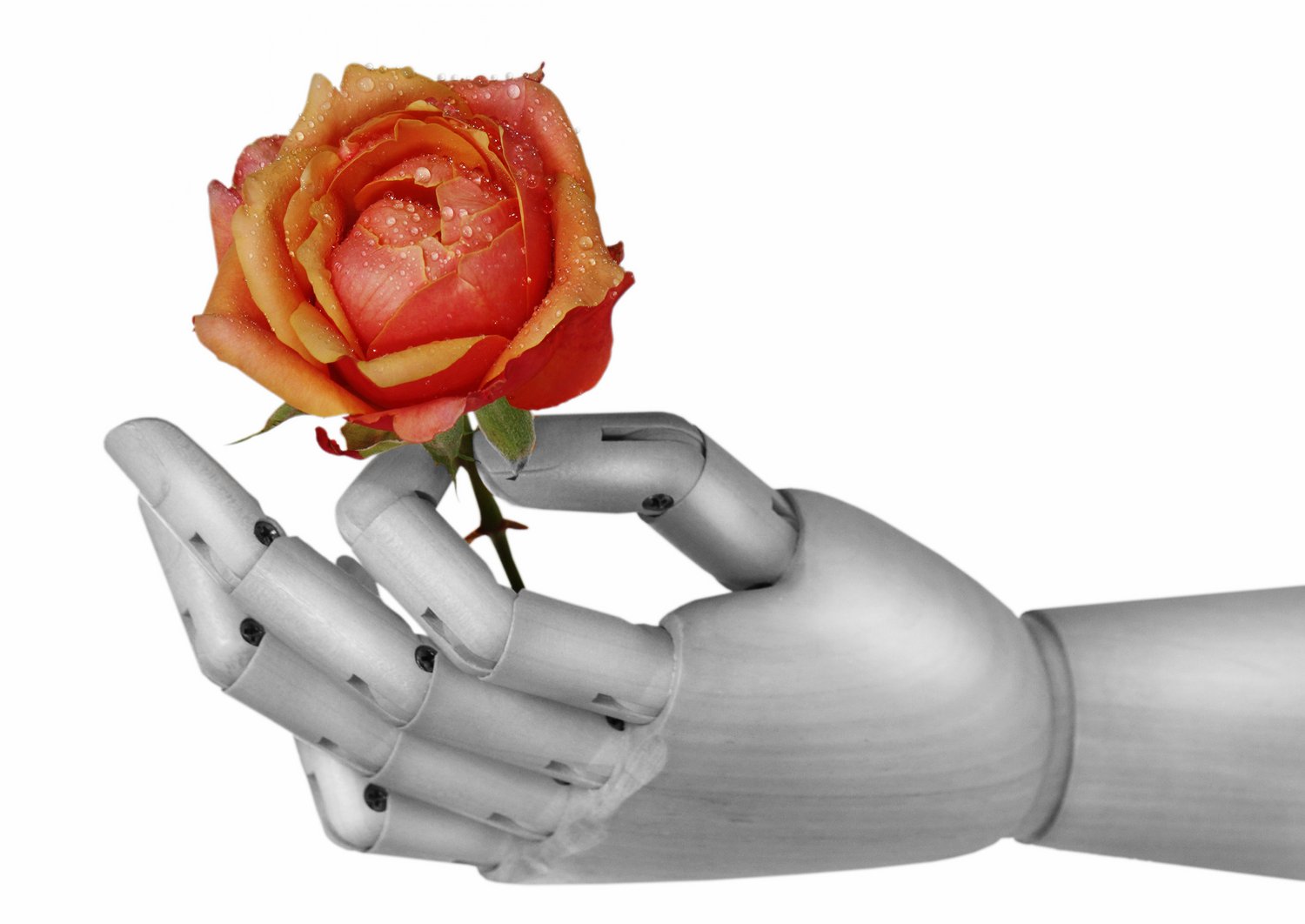

Soft robotic and compliant systems are the future of robotics for systems that are intended to collaborate with humans or are directly connected. In this context, it is essential to make the robotic grippers more collaborative. Gripping processes form a central role in this case. Objects that are to be lifted and moved must be held firmly enough. This is to prevent slipping, but the objects must not be damaged by the gripping process. Here, the measurement of both normal and shear forces plays an important role in order to be able to achieve the ideal ratio.

The sensor system developed should enable force measurements in 3D and thus make it possible to measure normal and shear forces separately. At the same time, this measurement system must be designed in such a way that it does not influence or limit the properties of the robotic gripper, i.e. it must be equally flexible.

Application areas

Robotics is finding increasing influence and application in more and more areas. The applications for the technology developed here are manifold: e.g. medical technology, collaborative robotics, but also the fields of consumer goods and wearables benefit from the developed methodology. Soft Robotic Systems are especially used where human-machine interaction plays an important role, e.g. in rehabilitation, robotic therapy and also for wearable medical assistance products (e.g. smart orthotics and prosthetics). Especially in areas with human interaction, reliable and accurate sensing of these robotic systems is essential.

Multidisciplinary collaboration

The project ROSE is based on an idea of the ADMiRE Lab of the Carinthia University of Applied Sciences. In order to be able to carry out the project in its entirety with all necessary competences, SAL joined as a partner.

SAL is responsible for the development of the sensor technology in this project. With the help of additive manufacturing technologies (AM) (aerosol jet printing, inkjet printing, screen printing) a sensor system based on the piezocapacitive principle is developed and manufactured. In the process, the sensor systems will be manufactured with the lowest possible use of resources in the sense of sustainability (green deal). These sensors will have appropriate flexible properties so as not to influence the characteristics of the Robotic Gripper to its disadvantage.

The Carinthia University of Applied Sciences contributes expertise in the field of robotics and 3D printing soft robotic systems as well as multi-material and lightweight construction competences. In particular, the integration into robotic applications is also being developed and optimized by the University of Applied Sciences. Elastomeric sensors using robotic 3D printing are also the focus of the work.

By combining these two areas of expertise, it will be possible to develop integrated soft robotic systems with high-resolution sensor technology and to optimize them in terms of their gripping properties.

Contact details ADMiRE Lab:

Dr. Lisa-Marie Faller

l.faller@fh-kaernten.at

+43 650 305 96 08